Facilities

High Reynolds number boundary layer wind tunnel

This wind tunnel has been specially designed for the study of the turbulent boundary layer by optical diagnostics. It is unique because of its dimensions (20m long, 2m wide and 1m high). It allows to obtain a boundary layer up to 30cm thick for velocities between 3 and 10 m/s with Reynolds numbers based on the momentum thickness up to 20 000. The test section has the particularity of being transparent along its entire length and of being temperature controlled. It can operate in open or closed circuit.

![[Translate to English:] Schéma soufflerie de couche limite](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/schema_soufflerie.svg)

Technical specifications

- Power of 37 kW

- Air velocity of 3 to 10 m/s at the beginning of the tunnel and stable at +- 0.5%

- Plenum chamber equiped with honeycomb and 4 low spacing filters

- Rectangular converging section of 3.9m x 2.79m, contraction ratio of 5.4

- Turbulence intensity in test section < 0.3%

- Refrigeration capacity of 37 kW

- Temperature range in test section between +5°C and +25°C

- Accuracy of ± 0.15°C

- squared section of 2m x 1m over 20.6m

- Fully transparent on 4 sides

- Flateness <0.5mm over 20m

- No irregularities greater than 0.1mm

Boundary layer properties

| X [m] | Ue [m/s] | δ [cm] | δ* [cm] | θ [cm] | H | Uτ [m/s] | Reθ | Reτ | P+ (x 10^-4) | ν/uτ[mm] |

| 19.2 | 3.38 | 27.3 | 4.55 | 3.33 | 1.36 | 0.1207 | 7590 | 2220 | -3.6 | 0.12 |

| 19.2 | 6.76 | 24.3 | 3.69 | 2.79 | 1.32 | 0.2337 | 12720 | 3840 | -2.1 | 0.06 |

| 19.2 | 10.09 | 24.2 | 3.51 | 2.70 | 1.30 | 0.3428 | 18360 | 5590 | -1.4 | 0.04 |

| X: | Position relative to the beginning of the test section |

| Ue: | External velocity |

| δ: | Boundary layer thickness |

| δ*: | Displacement thickness |

| θ: | Momentum thickness |

| H: | Boundary layer form factor |

| Uτ: | Wall shear stress velocity |

| Reθ : | Momentum thickness based Reynolds number |

| Reτ: | Wall shear stress based Reynolds number |

| P+: | Scaled pressure gradient |

| ν/uτ: | Wall unit |

Models

Mixers

In the industry, mixers are used to mix heterogeneous media, fluids and/or solids. They are used to promote chemical reactions, optimize mass or heat transfer for processes in various fields. Turbulence plays an important role in the mixing process, but the link between the two is not yet fully understood.

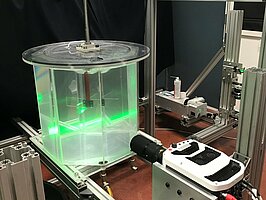

The mixer bench has a fixed frame on which the motor and part of the instrumentation are mounted. The tank is interchangeable depending on the measurement to be conducted. For the PIV, tanks have optical access or are completely transparent.

Main characteristics of the bench

- Nema 34 direct drive stepper motor of 12 N.m

- Torque measurement range from 0.05 to 50 Nm by strain gauge torque meter

- Fully adjustable rotor

- Measurements in water or other liquid

Rushton turbine mixer

This octagonal tank was designed to study the turbulence generated for different blade geometries. The rotor is based on a Rushton turbine design, with interchangeable blades. Anti-rotation (baffles) can be mounted in the tank to modify the flow, thus changing the properties of the generated turbulence.

![[Translate to English:] Organisme financeur [Translate to English:] Accès à l'organisme financeur : l'Europe s'engage en Hauts-de-France](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/europe_HDF.svg)

![[Translate to English:] Organisme financeur [Translate to English:] Accès à l'organisme financeur : Région Hauts-de-France](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/Logo_Re__gion_HDF.svg)

![[Translate to English:] Organisme de tutelle : CNRS [Translate to English:] Accès à l'organisme de tutelle : CNRS](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/logo_CNRS.svg)

![[Translate to English:] Organisme de tutelle : Centrale Lille [Translate to English:] Accès à l'organisme de tutelle : Centrale Lille](/fileadmin/_processed_/3/3/csm_logo_centrale_lille_cf284674ba.png)

![[Translate to English:] Organisme de tutelle : Université de Lille [Translate to English:] Accès à l'organisme de tutelle : Université de Lille](/fileadmin/_processed_/3/c/csm_ULille_logo_2fae4f0874.png)

![[Translate to English:] Veine d'essai soufflerie de couche limite](/fileadmin/_processed_/d/e/csm_soufflerie_735cccf493.jpg)

![[Translate to English:] Maquette 1 soufflerie de couche limite](/fileadmin/_processed_/2/0/csm_maquette3_3f20b3eac6.png)

![[Translate to English:] Maquette 2 soufflerie de couche limite](/fileadmin/_processed_/b/c/csm_maquette2_e95a197c98.jpg)

![[Translate to English:] Maquette 3 soufflerie de couche limite](/fileadmin/_processed_/3/1/csm_maquette1_6a86ef73f6.jpg)

![[Translate to English:] Maquette 4 souffelrie de couche limite](/fileadmin/_processed_/b/7/csm_maquette4_58d195e8db.jpg)