Services

For any request for services, studies or professional training, you can contact:

Some examples

Preliminary study for the optimization of the mixing performance of an industrial mixer with fractal geometry blades

Objectives

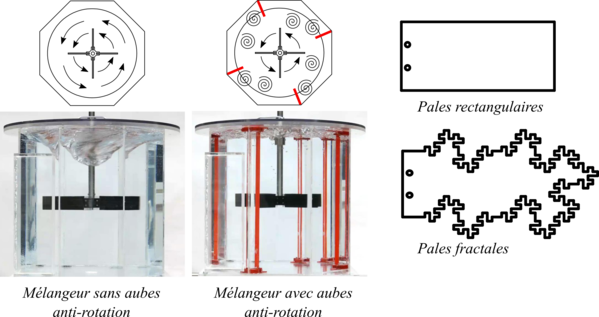

The idea is to study the using of fractal blade geometries instead of conventional blade geometries in industrial mixers. For this purpose, the mixing performance and the energy requirement of the mixer are compared according to the blade geometry for several mixer configurations. In the considered mixer where the flow is turbulent, the mixing performance is relative to the generated turbulence, it is thus necessary to characterize it.

Methods

The mixer considered is the mixer based on a Rushton turbine mixing transparent liquid water (necessary for the optical spatiotemporal measurement of turbulence). The measurement of turbulence is performed by 2D2C PIV (two components of the velocity in a plane) at high magnification with time resolution, thus a large part of the spatiotemporal scales of turbulence are resolved, allowing its fundamental characterization. Here, only the turbulence intensity in the mixer under the rotor is determined and is the indicator of mixing performance. The higher the turbulence intensity is, the faster the mixing in the fluid occur. The mechanical power driving the rotor is representative of the energy requirement and is measured by a strain gauge torque meter mounted on the motor shaft.

Several configurations are tested:

- General mixer configurations: with and without anti-rotation blades (baffles)

- Rotor speeds: two different speeds

- Blade configuration with identical swept area: rectangular blades and fractal blades

Results

The results show a significant gain when using fractal blades instead of rectangular blades with the same swept area, whatever the mixer configuration. Thanks to the fractal blades, the turbulence within the mixer is more intense while requiring less energy to be produced, as can be seen in the table below. There is at least a significant effect of fractal blades. This preliminary study demonstrates the interest in using fractal blades in industrial mixers, it is however necessary to in-deep on a case by case basis in order to optimize the fractal geometry according to the type and use of the mixer.

| No-baffles configuration | Turbulence intensity [%] | Advantage [%] | Mechanical power [W] | Advantage [%] |

| fractal blades, rotation 2 Hz | 67,7 | 22,6 | 5,0 | -6,2 |

| rectangular blades, rotation 2 Hz | 52,4 | XX | 5,3 | XX |

| fractal blades, rotation 3 Hz | 76,8 | 30,3 | 12,4 | -10,4 |

| rectangular blades, rotation 3 Hz | 53,5 | XX | 13,9 | XX |

| With-baffles configuration | Turbulence intensity [%] | Advantage [%] | Mechanical power [W] | Advantage [%] |

| fractal blades, rotation 1 Hz | 46,9 | 5,3 | 2,6 | -23,1 |

| rectangular blades, rotation 1 Hz | 41,6 | XX | 3,3 | XX |

| fractal blades, rotation 1,5 Hz | 44,9 | 0,6 | 7,6 | -23,4 |

| rectangular blades, rotation 1,5 Hz | 44,3 | XX | 9,9 | XX |

![[Translate to English:] Organisme financeur [Translate to English:] Accès à l'organisme financeur : l'Europe s'engage en Hauts-de-France](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/europe_HDF.svg)

![[Translate to English:] Organisme financeur [Translate to English:] Accès à l'organisme financeur : Région Hauts-de-France](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/Logo_Re__gion_HDF.svg)

![[Translate to English:] Organisme de tutelle : CNRS [Translate to English:] Accès à l'organisme de tutelle : CNRS](/fileadmin/user_upload/plateforme-experimentale-turbulence/images/logos/logo_CNRS.svg)

![[Translate to English:] Organisme de tutelle : Centrale Lille [Translate to English:] Accès à l'organisme de tutelle : Centrale Lille](/fileadmin/_processed_/3/3/csm_logo_centrale_lille_cf284674ba.png)

![[Translate to English:] Organisme de tutelle : Université de Lille [Translate to English:] Accès à l'organisme de tutelle : Université de Lille](/fileadmin/_processed_/3/c/csm_ULille_logo_2fae4f0874.png)